Custom

fabrication represents a large part of CFI's business. Production

requests come in from individuals as well as businesses, and

typically entail the creation of custom molds and engineered

parts.

Current Projects:

CFI made these giant size Christmas ornaments, which are featured at (among other places) Rockefeller Center.

CFI, in 2013-2014 manufactured special array canisters for General Dynamics.

In 2014-2015, CFI has manufactured more architectural pieces such as the unit constructed decorative window unit

used at Searstone in Cary, NC and many construction pieces such as soffits, rafter tails, window surrounds, and other

exterior finishing pieces for buildings at Liberty University in Lynchburg, VA.

Wind Tunnel Tail Cone for Testing the Aerodynamics of NASCAR Autos

Tooling and Products for the Commercial Furniture Group (CFG). Molded Booths for Fast Food Restaurants. |

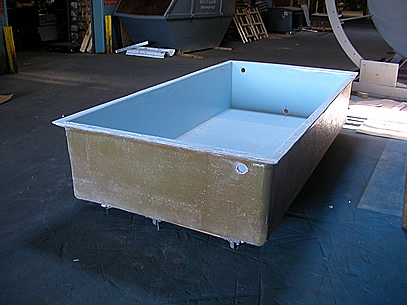

| Landscaping Pool |

Fish Farm Tank |

|

|

|

|

|

|

JARRETT BAY 32' Fishing Boat

| |

| The finished Jarrett Bay 32 Prototype Sport Fishing Boat. Parts built by CFI. This prototype boat did 50 mph with the engines pictured. The hull weight with stringers and bulkheads is 3000 lbs. The boat was hand laminated with vinylester resin and vectorply fabric. |

|

|

| View of the Jarrett Bay 32 cockpit and console. |

The first sea trial of the Jarrett Bay 32.

|

|

|

| The first Jarrett Bay 32 hull produced by CFI. |

The second Jarrett Bay 32 hull produced by CFI. |

|

|

| CFI Builders hand laminating a Jarrett Bay 32 hull using all Vinylester Resin and Vectorply Glass. |

CFI Builders installing stringers and bulkheads in one of the first Jarrett Bay 32 hulls. |

|

|

|

CFI built the molds (above) and is building the parts for the Jarrett Bay 32' Sport Fishing Boat. |

|

STEPS FOR AEROSPACE INDUSTRY |

CFI builds these fiberglass steps that have no metal parts and therefore do not produce sparks when moved around which makes them ideal for use in production envirnoments that use flammable liquids or gases such as the aerospace industry. |

|

|

Architectural Project for The State Legislature Building |

CFI installed a hand laminated fiberglass liner in four rooftop planters at the NC Legislature. The planters were leaking and needed a major refit. The fiberglass was applied and then sealed with a special roofing gelcoat. After passing all water tests, the planters were then refilled with dirt and trees, and opened to the public.

|

|

|

|

|

Drain opening before |

Applying the fiberglass |

Pyramids before |

Pyramids before |

|

|

|

|

Drain opening after |

Gel coat application |

Pyramids after |

Finished rooftop planter |

|

Weather Data Instrument Parts |

GEM-2A helicopter-towed instrument package built by Geophex, Ltd. In Raleigh, NC. CFI fabricated portions of the conical drag-skirt assembly shown at the rear of the package. CFI also fabricated hemispherical nosecones and other components. GEM is a registered trademark by Geophex.

|

|

|

FIBERSTEPS |

In the fall/winter of 2002, CFI was building fiberglass steps called Fibersteps (patent pending) for housing projects in Wytheville VA. The Fibersteps are molded individually and then locked together when installed. It's a clean, simple design that is rust-proof and easy to install. View photos.

|

|

2003 Projects

|

| |

|

|

|

Custom dryer doors, as seen in the two photos (r: door open, l: door closed) on the left.

|

|

|

|

|

Custom fiberglass duct for Guilford Mills, Greensboro, NC. Over 58 feet in length and 34"in diameter this duct was made of acid resistant and fire retardend resins. The hopper was custom made and over 5' tall! See photos to the right and above. |

|

|